We need partnership and innovation to achieve a more sustainable future

Monica Gimre is President and CEO of Sidel, a leading global provider of packaging solutions for beverages, food, home and personal care products. The company is at the forefront of one of the world’s biggest sustainability challenges: packaging. How we safely package and transport our products, and how we dispose of our packaging, is central to our attitudes to energy, waste and recycling.

How is the packaging industry stepping up to the sustainability challenge?

We saw from the COP26 climate change summit that if the world is to limit global warming to 1.5°C or less by the end of the century, we all have to really increase our efforts.

The packaging industry is taking climate change challenge very seriously. Sidel’s customers, which include well-known global brands and companies, are setting ambitious targets to reduce greenhouse gas emissions, not only for themselves but also their whole supply chain.

We all recognise that progress on sustainability relies on cooperation, especially if you consider that analysts expect to see a 2.6% rise in sales of packaged consumer goods by 2025 – that’s another 423 billion units.

How are you going about it at Sidel?

We’ve really stepped up our commitments. Having agreed only a year ago to reduce greenhouse gas emissions at our own sites and facilities by 30 percent by 2030, we have now moved those targets up a gear, pledging to halve our emissions in that timeframe. So, we are now committed to being on the 1.5°C pathway and being part of the best efforts to limit global warming.

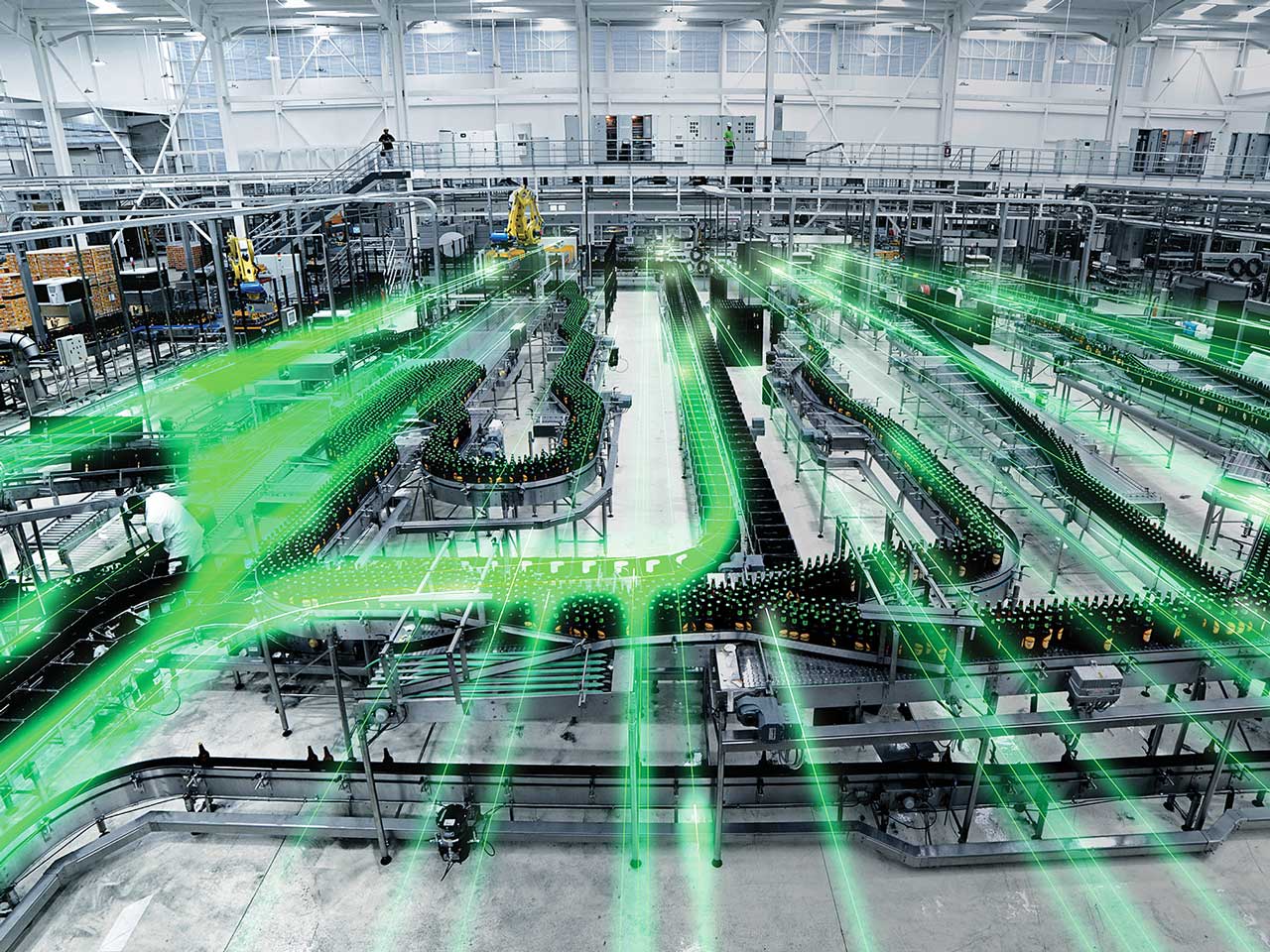

All our sites will be 100% green energy-powered by the end of this year. Our new site in Santa Maria da Feira, Portugal (pictured) is a good example, featuring intelligent lighting control and electric car charging stations.

As an equipment manufacturer, what can you do to influence the supply chain?

Sidel is fully embracing this challenge. We want to be at our customers’ side and to lead our suppliers towards a more sustainable future: it is only through working with partners that we can make a difference. We make sure we understand their sustainability goals and we’ve let them know they’re not alone! It takes continuous dialogue and we will use all our technical knowledge and smart data analytics to help them.

We’ve already reduced the energy consumption of our machines – our blowers now use 45% less energy. We also halved the water consumption of our bottle washers and have developed a digital suite that can help customers monitor and adjust their production line energy consumption. We’ve upgraded existing lines, so they are more energy-efficient and sustainable, which last year saved more than 1,500 tonnes of CO2. As an example, helping our UAE-based customer Zulal move to a new integrated packaging line configuration brought them energy savings of 56%.

Our designers can optimise product design to make packaging that uses less material and fewer resources when it is blown and transported. Our moulding technology allows bottles weight reduction, cutting down on material use as well as energy consumption and transport emissions.

We help customers deal with regulatory changes – for example, the move to tethered caps which will become mandatory on all bottles in Europe and the UK from 2024 to minimise litter.

We’re committed to reducing emissions on everything we buy and sell by 25% by 2030, against a 2019 baseline. We recently started a supply chain initiative to support our suppliers to start their own commitment and track progress against our common goal.

Our efforts have been recognised as we have been given an A- rating for our supplier engagement by CDP (Carbon Disclosure Project), a global environmental non-profit organisation.

Where are the regulatory and government pressures on the packaging industry?

There is now a general request for manufacturers to take on more responsibility for waste management, with the intent of making a drastic shift from a linear to a circular economy model. Currently 63 nations have enacted Extended Producer Responsibility measures to encourage schemes such as product takeback, deposit-refund, and waste collection guarantees. More governments are open to funding and creating better recycling infrastructures.

Plastic packaging is often seen as the enemy of the environment. How can you make a positive case for it?

It’s hard to change perceptions, but the truth is that lifecycle analysis shows that plastic, and PET in particular, has the best carbon footprint among materials currently available. If it is properly collected and recycled, PET can offer the best answer to the current sustainability challenge.

We need to see packaging as a resource, not a waste. If we can prevent it from ending up in the environment by keeping it in a circular economy loop, PET plastic packaging can play a pivotal role in protecting and distributing our most precious products.

Since 2019 we’ve been a signatory of the New Plastics Economy Global Commitment, launched by the Ellen MacArthur Foundation and UN Environment Programme to accelerate the transition to a circular economy.

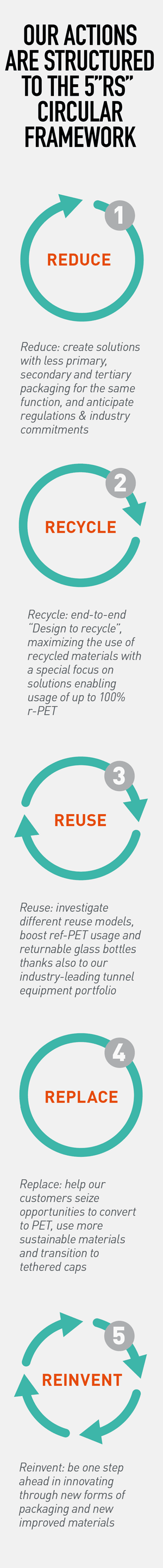

Like it or not, plastic packaging is going to be with us in the near term and indeed is expected to rise, especially in Asia Pacific, the Middle East, Africa and India. So, we have to make this growth more sustainable, and for that we all need to engage all the 5Rs levers: Reduce, Recycle, Reuse, Replace and Reinvent (see diagram).

Reduce is the first and most important action, and it needs to start from the actual design of the packaging. Reuse will come to the fore, with more refill options for the consumers, both at home and on the go. Increasing Recycling is of pivotal importance, both in quantity and in quality: return schemes such as reverse vending machines that incentivise consumers are proving to be a great tool to achieve both. Easier-to-recycle solutions by using one single mono-material layer instead of many layers of multiple materials are on the rise.

PET is already the most recycled type of plastic, thanks also to its ability to achieve food grade quality even when recycled. It will become more prevalent in line with the ambitious targets the big brand owners have set for themselves in terms of percentages of recycled PET, known as r-PET, in their packaging.

We’re also actively seeking to Replace with new bio-sourced or bio-based materials and looking at ways to completely Reinvent the way packaging is conceived.

What is preventing the widespread adoption of recycled PET?

The amount of recycled PET in packaging is increasing but progress is slow, with an estimated global average of 8% compared to 5% in 2018. In Europe, the average is already 15% and is projected to be around 35% in 2030.

Sidel offers a testing and validation service to help customers deal with r-PET’s inherent variability and we have set up our own pilot-scale PET recycling line near Le Havre in France. Sidel has also signed up to R-Cycle, the open tracing standard for sustainable plastic packaging. It provides a digital product passport, and is a big step towards the implementation of a genuine circular economy and highly efficient process chains. Partners from around the world can record and retrieve all the relevant properties of the packaging to improve their product sustainability, quality, and manufacturing process.

It takes time to put recycling facilities in place, but we are seeing a lot more investment in recycling facilities in Europe. Materials and chemicals companies such as Eastman, Indorama and Carbios have recently announced major recycling initiatives in France and another, Suez, is creating new recycling capacities in Belgium.

Overall, are you optimistic or pessimistic about the role the packaging industry will play in sustainability?

I am optimistic because I believe in the resourcefulness of our engineers and a growing collective determination to set and meet tough targets. In the end, it will be a combination of innovation, ingenuity, and collective will from regulators, industry and consumers to make the best use of our precious resources.